Enersis.com.tr

Measuring capsule heat meter G54 / G55Measuring capsule heat meter with optical interface and external modules for retrofitting. Thanks to integrated modules, the devices can be equipped with the required communication technology ex factory.

For use in the Q opto and Q basic systems or through an integrated communication module in the Q M-Bus system. Can be retrofitted with external modules for use in the systems Q M-Bus, Q walk-by and Q AMR.

As series G55 with combined heat and cold metering.

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

The capsule meters G54 or G55 have been designed as replacement meters and are used wherever a heat meter housing (single-pipe connector) for capsule meters with a 2 inch coax thread is available. Due to their design height, the meters are general y fitted with a detachable calculator unit that can be fitted at a distance of up to 25 cm away from the volume meter.

With model G55, the combined measurement of heat and cold energy is possible. The main areas of application are in central heating systems where the heating energy is outputted individual y to different consumers.

This is meaningful in: Apartment buildings Offices and administration buildings

Typical users are: Metering service companies Housing associations Property management companies Specialist companies for sanitary, heating and air-conditioning technology

2" capsule heat meter G54 or combined 2" capsule heat/cold meter G55

for indirect instal ation of the temperature sensors

Fits in al 2" coax-EATs Detachable calculator unit Optical interface for external communication modules Internal communication modules for M-Bus and impulse available ex factory Mains-independent, for local use, 6 or 10-year lithium battery PTB-approved, approval no. D 22.12/05.02 Values are measured by two platinum PT 1000 resistance thermometers and one hydraulic

impel er wheel sensor (2" coax) with inductive impel er wheel scanning with carbide-sapphire bearings for low-wear and reliable long-term measuring operation (the counter housing (EAT, EAS) must be provided on site).

High resolution thanks to 7-digit LC display that indicates current value, old value, check

number and many service and operating parameters

Additional display of 18 monthly values with date Storage of the maximum supply flow and return flow temperatures as wel as the maximum

current flow with date

Programming of a due date can be carried out on-site via the optical interface Add-on modules for radio or M-Bus communication as wel as impulse output and RS 232

modules can be retrofitted at any time on-site via the optical interface

Thanks to integrated modules, the devices can be equipped with the required

communication technology (M-Bus or impulse output) ex factory

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Type summary

0.6 m³/h for immersion sleeve and direct measurement - temperature sensor 5.0 x 45 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

1.5 m³/h for immersion sleeve and direct measurement - temperature sensor 5.0 x 45 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

2.5 m³/h for immersion sleeve and direct measurement - temperature sensor 5.0 x 45 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

G54 / G55 for external installation spots

0.6 m³/h for immersion sleeve measuring - temperature sensor 6.0 x 50 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

1.5 m³/h for immersion sleeve measuring - temperature sensor 6.0 x 50 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

2.5 m³/h for immersion sleeve measuring - temperature sensor 6.0 x 50 mm

with 1.5 m temperature sensor cable

with 3.0 m temperature sensor cable

G54 / G55 with internal module

Internal communication modules

M-BUS module

* x = any option code

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Further order options

Volume measurement in heat pipes

Immersion sleeve and direct measurement, temperature sensor

5.0 x 45 mmImmersion sleeve measurement, temperature sensor 6.0 x 50 mm

* x = any option code

Further accessories

Order data

Programming key for due date programming

Remote display with wall bracket,

inc. plug-in cable 2.5 m long

Extension cable 5 m long

M-Bus cable with sealable plug,

2-pole for M-Bus, 3.0 m long *

Impulse cable with sealable plug,

2-pole, 3.0 m long for G54 *

4-pole, 3.0 m long for G55 *

* only for devices with integrated modules

The part numbers shown in the type summary must be quoted in orders. If a due date other than January 1 is required, the type description must be supplemented by the required month in the order (the due date is always the first of the month). Ordering example for a heat meter with 110 mm instal ation length and May 1 as due date: G54/0000-00, due date: May

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

The heat meter G54 / G55 comprises a pair of precise temperature sensors and a volume meter which is instal ed in an existing single-pipe connector with 2 inch coax thread. An electronic calculator unit continual y calculates the difference in temperature between the supply and return flow and multiplies the value by the flow rate. The result of this (current heating or cooling capacity) is cumulated, displayed or forwarded to a data-processing system by radio or cable.

The heat meter G54 / G55 is a heat meter that can be extended by different internal and external modules. Internal modules are integrated into the device during production in the factory.

The G54 / G55 has two communication interfaces available. 1. The optical interface Q opto (1107) which is accessible from the outside. This al ows

programming and retrofitting work on the G54 / G55 on-site at al times. The heat meter can be retrofitted for radio or other communication means. The respective modules are simply mounted on the calculator unit.

2. The internal module interface for internal impulse output or M-Bus modules. In the case

of integrated modules, the information is forwarded via a permanently mounted, threaded and sealed cable connection (impulse output and M-Bus).

Measuring principle

The hydraulic sensor (volume meter) is based on the multi-jet impel er wheel sensor principle.

The impel er wheel is scanned using changes in field strength in a coil depending on the impel er wheel position. There is no accumulation of magnetite, which could lead to blockage of the impel er wheel.

Determining water consumption

Using the measured difference in temperature between supply and return flow, the flow rate and the calculated thermal coefficient, the heat quantity is shown on the LC display in physical units (kWh, MWh, MJ, GJ) fol owing an internal calculation process. To increase measuring accuracy, the density and enthalpy values are determined for every measurement and integrated into the calculation.

Storing the consumption values

The heat consumption values are continual y cumulated. The current status is stored at the beginning of the due date. The due date can be set with the aid of a programming key; January 1 is set as the 01. standard due date (see «Ordering» section)When the annual consumption is stored, the heat meter calculates a plausibility figure. This can be read out together with the due date value and checked in the bil ing program. This al ows incorrect display readouts (e.g. "switched digits") to be detected. The stored due date value remains in place for one year.

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Device states, display units and consumption values are shown via the LC display on several levels (up to 5 levels). The heat meter is equipped with a key that can be used to switch between the individual display steps and levels. The display includes the fol owing values:

Current heat quantity and,

Temperature difference

with G55, cold quantity

Current energy flow

Old value heat quantity and,

High-resolution heat quantity

with G55, cold quantity

Volume per input impulse

Check number heat quantity and,

with G55, cold quantity

Any module instal ed

Storage date and consumption values

Cumulated volume

for the last 18 months for quantity of heat

and cold (with G55)

Supply flow temperature Return flow temperature

Current heat quantity

Segment test – everything on

Segment test – everything off

Old value heat quantity

(meter count on the due date)

Check number heat quantity

(plausibility figure reg. old value)

(day the old value is formed)

Current cooling quantity

Optional display for combined heat/cold

Old value cooling quantity

(meter count on the due date)

Old value cooling quantity

(plausibility figure reg. old value)

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Supply flow temperature

Return flow temperature

Temperature difference

Current energy flow

(since factory test)

Module: not instal ed

(no integrated module)

(primary address = 012)

Optional display. Depending on the module

Module: Impulse output

instal ed or heat meter type,

(impulse value = 1 kWh)

this display appears additional y.

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Latest monthly value

Respective monthly value

18 monthly values

Oldest monthly value

Respective monthly value

Optional display.

Latest monthly value

Depending on the module instal ed or heat meter type, this display appears

Respective monthly value

additional y.

Cooling quantity

18 monthly values

Oldest monthly value

Respective monthly value

Special displays Error messages

The heat meter is self-monitoring and can display errors established.

These messagse alternate with the current display.

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

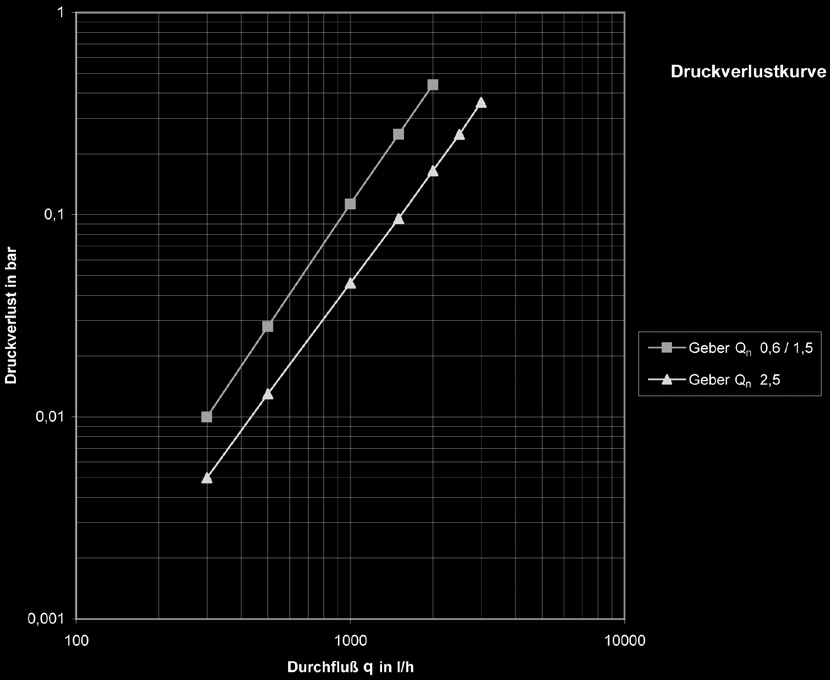

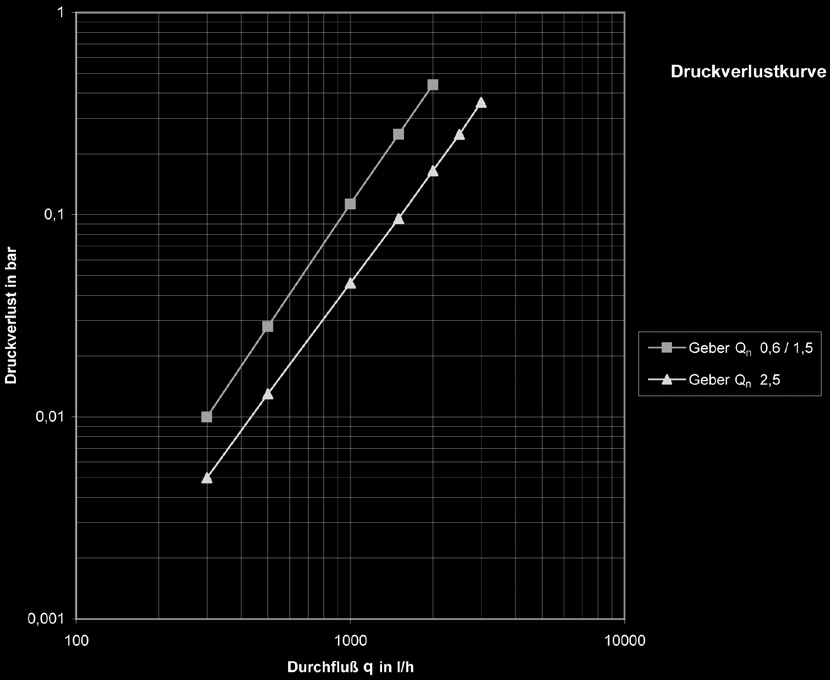

Sensor Qn 0.6 / 1.5

Loss of pr

Flow rate q in l/h

Norms and standards

Directive 1995/5/EC (R&TTE Directive)

Legislation concerning radio systems and

telecommunications equipment (FTEG)

Interference resistance

Emitted interference

IP protection rating

IP54 according to EN 60529

Heat meter

Quality of heat medium

VDI guideline 2035

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

General device data

Installation position

horizontal/vertical

Metrological class

Minimum flow Qmin

0.030 (0.015) m³/h

0.050 (0.025) m³/h

Maximum flow Qmax

Loss of pressure at Qn

Nominal pressure PN

Nominal diameter

Connection sizes and dimensions

Installed length

The heat meters G54 / G55 are delivered as replacement meters and

installed in the EATs already available on site.

Temperature range

Maximum temperature

(for brief periods)

Calibrated temperature difference

Minimum temperature difference

Type of temperature sensor

Cable length of temperature sensor

1.5 (opt. 3.0) m

1.5 (opt. 3.0) m

Energy supply

> 6 (opt. 10) years

> 6 (opt. 10) years

Protection rating

Length of calculator unit cable:

Display levels

kWh (opt. MWh, MJ, GJ)

kWh (opt. MWh, MJ, GJ)

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

G54 / G55 with volume meter

(EAT not included in the scope of supply)

(*) Dimensions can vary depending on EAT variant

QunDIs GmbH

Sondershäuser Landstraße 27

Bahnhofstraße 10

99974 Mühlhausen / Germany

78112 St. Georgen / Germany

Tel.: +49 (0) 3601 46 83-0

Tel.: +49 (0) 7724 93 89-0

Fax: +49 (0) 3601 46 83-175

Fax: +49 (0) 7724 93 89-310

e-mail: [email protected]

e-mail: [email protected]

The information in this data sheet only contains general descriptions or product characteristics, which may not always apply in particular

application cases and/or may be subject to change through further development of the product.

Required product characteristics are then binding if they are expressly agreed when the contract is drawn up.

2010 QUNDIS GmbH. Subject to change

Measuring capsule heat meter G54 / G55

DST1-QHEA-GB0 G54

Source: http://www.enersis.com.tr/files/G54_DS.pdf

ES-T1 LED RGB Controller Manual ES-T1 LED RGB Controller Manual 2. The charging methods for remote control LED RGB Controller 1. Please use USB cable to connect with the matched 5 V charger or insert into the USB interface on the computer.2. The blue indicator light flickers while charging, and turns green when finish charging.3. No memory effect in the lithium battery of remote control. Follow the standard charging procedure even for the first three times, no need over charge.4. Red indicator light flickers meaning low power and need to be charged. charging in low battery will affect life of battery.

This article was downloaded by: [115.85.25.194]On: 12 April 2012, At: 19:39Publisher: RoutledgeInforma Ltd Registered in England and Wales Registered Number: 1072954 Registeredoffice: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK NORA - Nordic Journal of Feminist andGender ResearchPublication details, including instructions for authors andsubscription information: