Ek220 en03, 20/02/2012

Volume conversion device with fl exible data logging function and confi gurable serial interface

- Volume conversion for billing purposes

• T, PT, PTZ volume conversion

- Data logging for different applications

• Conforms to European standard

- Monitoring of measurement values und station functions

Brief information

• Compressibility calculated

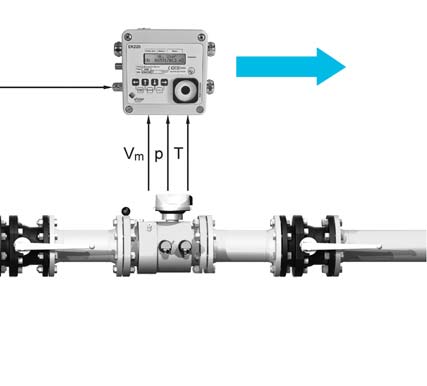

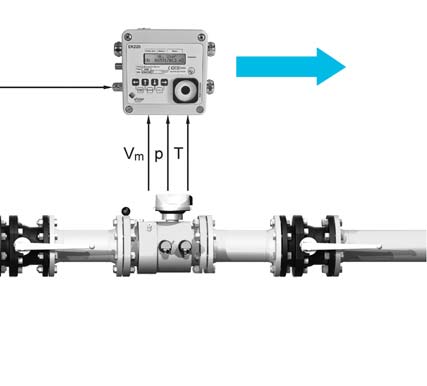

The EK220 is a battery-operated volume convertor. The device records the low frequency

in accordance with different methods

operating volume pulses of a gas meter, measures the operating pressure and tempera-ture of the gas and calculates the compressibility K as well as the conversion factor C. The

• Flexible, integrated data logging

standard volumes, standard fl ow rates and operating fl ow rates can be calculated using

this initial data.

• High accuracy

The volume convertor consists of a central unit with either an integrated or external pres-

• Mains-free operation

sure sensor and a temperature sensor. The sensors are permanently connected to the

• Suitable for use in

unit. The compressibility K can be programmed as a constant for all gases or calculated

Zone 1 hazardous areas

according to various methods of calculation.

• Three digital inputs

The device is also available without a pressure sensor and can be used as a temperature

• Four freely programmable outputs

conversion device. In this case the gas pressure for the volume conversion will be consid-

• - IEC 62056-21

ered with a fi xed value, which has to be confi gured during the commission of the device.

The EK220 can be used in many applications in the fi eld of natural gas measurement and station monitoring thanks to four digital outputs, a fl exible data logging function in con-

• Optical interface for parameterisation

junction with a freely confi gurable serial interface and different communication protocols.

and readout (IEC 62056-21)

• Integrated serial interface can be used

Additional components for explosion-proof isolation of the interfaces and the intrinsically

as RS232 or RS422/RS485

safe external voltage supply, and for data communication, extend the range of use of the volume convertor.

• Second pressure sensor for monitoring

purposes (option)

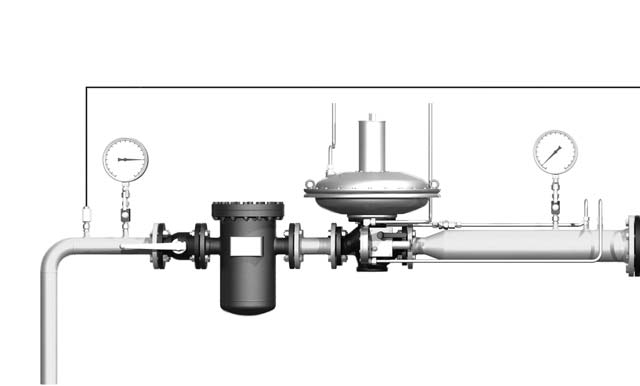

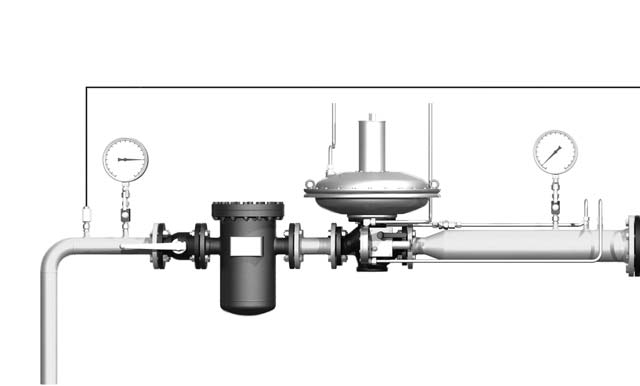

Station monitoringIn addition to volume conversion and data logging, the EK220 may be used for the fl ex-ible data recording of different measurements and, in conjunction with either a modem or RTU, for system monitoring.

Two additional digital inputs can be used for registering and monitoring the signal sen-sors such as the safety shut-off valves on regulators, the differential pressure switches in fi lters or for a simple door contact. The signals from such sensors can be saved in an archive as an event and can also be sent as a spontaneous message by text message or by e-mail via a connected modem.

The volume convertor may optionally be fi tted with a second external pressure sensor, which allows to record the inlet or outlet pressure of the measuring system, or to monitor its limit values.

EK220: Volume conversion device with flexible data logging function and configurable serial interface

Display and operation

components. In RS485 mode, bus opera-

puts, they allow forwarding of the volume

tion is also possible, in order to read out

pulses determined for a measuring cycle in

The current values and parameters can be

two volume convertors via a communica-

the form of pulse packets. When used as

shown on the two-line, alpha-numerical

tion module (modem, RTU). In compliance

status outputs, messages and warnings

display and changed if required. The use of

with the specifi cations laid out in the ATEX

can be signalled on the basis of different

four arrow keys guarantees simple naviga-

approval, the interface may also be used in

results (e.g. exceeding the minimum or

tion of data arranged in lists. Each value is

hazardous areas in any confi guration.

maximum consumption values or meas-

displayed with a clear description and the

ured values, sensor errors, time synchroni-

relevant unit.

sation signals, etc.). The outputs can either

Communication protocols

be secured against unauthorised changes

For everyday operation, the most impor-

by supplier lock or calibration lock.

tant values are combined in a confi gurable

The EK220 supports various communica-

user list. The display range can be limited

tion protocols. Invoice-relevant data or

The volume convertor may also optionally

to this list, which will guarantee simple op-

process and operating data for network

be fi tted with a second pressure sensor.

eration of the volume convertor at the me-

management can therefore be used si-

Depending on the system confi guration,

tering point. At the touch of a few buttons,

multaneously in many established central

the measuring system's inlet or outlet pres-

the current meter readings and the main

call-up systems and EDM systems.

sure can thus be registered in one of the

operating parameters can be checked.

fl exible archives and the limit values can

Using the communication protocol in ac-

also be monitored there. The system's sta-

cordance with IEC 62056-21, all param-

tus can also be continuously monitored

Data logging function

eters can be read and changed and the

when it is connected to a SCADA system.

archives can be read out. All protocol in-

The integrated, event-triggered data log-

formation is disclosed and is available on

ger supports different archive and logbook

request for the development of own appli-

cations and call-up systems.

The power supply for the unit is provided

Six archives can be freely confi gured, i.e.

As an alternative to the protocol in accord-

by a lithium battery. In standard operation,

the values that are to be recorded, the

ance with IEC 62056-21, the Modbus proto-

the service life of the battery is 5 years. An

events triggering registration, as well as

col can also be used for data communica-

optional additional battery can be used to

the recording interval (measuring period),

tion via the internal interface, which allows

double the battery life. The current operat-

can be selected as required. Depending

connection to SCADA systems. For using

ing status of the volume convertor is taken

on an archive's confi guration, the data can

the Modbus protocol the operating modes

into account when calculating the remain-

be saved for up to one year, or longer.

ASCII, RTU and TCP are supported.

ing battery capacity. If the battery life is 3 months or less, the corresponding indica-

Along with the data logging archives, the

In order to guarantee the greatest fl exibility

tion appears in the display. In addition, this

volume convertor offers three logbooks,

as regards different requirements and ap-

information can also be called up via the

with which the volume convertor's opera-

plications, the data elements, associated

volume convertor status register. The bat-

tion can be monitored constantly. The event

Modbus addresses and data formats can

tery can be replaced without damaging the

logbook saves the last 500 messages for

thus be freely confi gured.

internal seals. All parameters are saved in

events and status changes. In the change

a non-volatile memory.

logbook the last 200 setting changes are

In addition to the process data and simple

registered and up to 50 changes to pa-

parameter, also the content of the different

In addition, it is also possible to use an ex-

rameters and values requiring offi cial cali-

archives can be read by using the Modbus

ternal power supply. In this case, the bat-

bration are documented in the calibration

tery remains in the unit and guarantees the

archive (Certifi cation data log).

unit functions, including if there is a failure of the external power source.

Additional functions

Communication interface

Two additional digital inputs can be used

The programming or readout of the device

either as pulse inputs or status inputs for

at the station is performed via the optical

various applications, such as station moni-

For wall mounting, the housing of the

interface (IEC 62056-21) on the front panel.

toring and pulse comparisons, for exam-

EK220 is equipped with boreholes. It can

also be fi tted directly to the meter or gas

The unit's serial interface can be freely con-

pipe using an attachment bracket.

fi gured and can be operated in RS232 or

Four freely programmable digital outputs

RS422/RS485 mode. It allows connection

enable a range of information to be trans-

to modems and other communication

mitted. When programmed as pulse out-

Product data sheet

Second pressure sensor for station monitoring (option)

- Connection to 2nd p-sensor

- Recording in the archive(s) (confi gurable)

- Supervision of limits (event handling)

via- GPRS (TCP/IP)- Direct connection- Ethernet (TCP/IP)- RTU

Flexible data logging and logbook function

Standard confi guration

Date, time, Vb, VbT, MPmaxVb, dailymaxVb, Vm, VmT, MPmaxVm, dailymaxVm

Date, time, Qmmin, Qbmin, Qmmax, Qbmax, pmax, pmin, pØ, Tmax, Tmin, TØ, k-value Ø

Date, time, Vb, VbT, Vm, VmT, pØ, TØ, k value Ø, C factor Ø, status

Date, time, Vb, VbT, Vm, VmT, pØ, TØ, k value Ø, C factor Ø, status

1 minute - 1 month

Date, time, Vb, VbT, Vm, VmT, pØ, TØ, k value Ø, C factor Ø, status

1 minute - 1 month *3

Date, time, Vb, VbT, Vm, VmT, pØ, TØ, k value Ø, C factor Ø, status

1 minute - 1 hour *3

1 minute - 1 month *3

Date, time, event

Date, time, parameter address, old value, new value, information on all locks

Certifi cation data log Date, time, parameter address, old value, new value, information on all locks

(every change) *4

*1 depends on confi guration of archive (interval, content)*2 by using the standard confi guration*3 besides periodic recording specifi c events can be selected to trigger recording*4 records only the changes of certain parameters, which are under the access right of the calibration lock (function can be switched off)

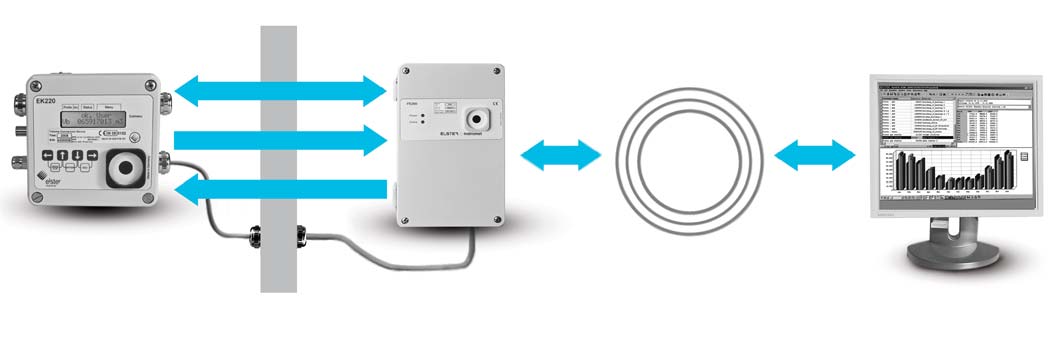

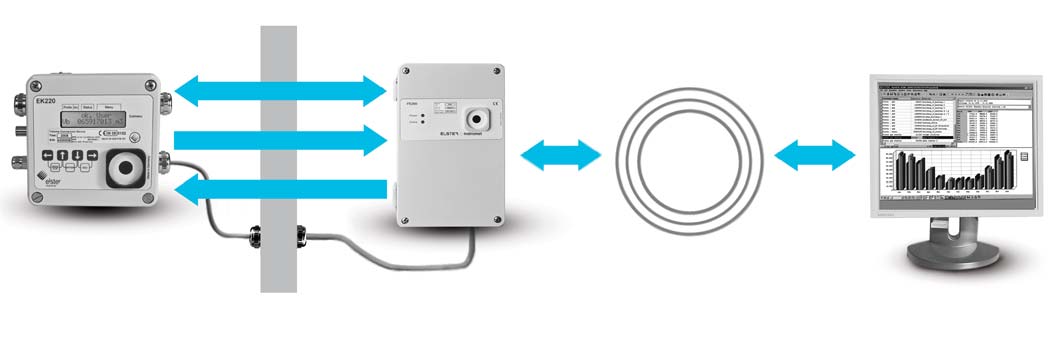

FE260 function extension unit – a fl exible interface between EK220 and energy data management

in hazardous area

- Volume conversion

- Ex-barrier data interface

- Ex-barrier digital outputs

- Modem (PSTN, GSM, GPRS, etc.)

- Intrinsically safe power supply for EK230

The Ex-barrier of the serial interface and

In addition, the intrinsically safe power sup-

of a modem for data communication or an

the pulse outputs of the volume convertor is

ply of the volume convertor is guaranteed.

interface for connection to other devices.

provided by function extension unit FE260.

The unit's modular concept allows the use

EK220: Volume conversion device with flexible data logging function and configurable serial interface

Cast aluminium, wall or meter mounting

H 126 mm x W 120 mm x D 90 mm (not including connections)

Approx. 1.5 kg (including batteries)

Metrological approval

Conforms to the European standard EN 12405-1:2005 +A1:2006MID DE 08-MI 002-PTB 001 volume conversion device (PTZ-conversion)MID DE 08-MI 002-PTB 002 temperature volume conversion device (T-conversion)

Ex Certifi cation

ATEX Zone 1, Ex ia [ia] IIC T4 (with Elster battery type 73015774) orIEC Ex Zone 1, Ex ia [ia] IIC T4 (with Elster battery type 73020663)

IP 66 (suitable for outdoor installation)

Ambient conditions

Temperature: -25 to +55 °C

Battery power supply

1 lithium battery 3.6 V, size D (service life > 5 years under standard operating conditions)Optional additional battery to double the service life

External power supply

5 – 10 V DC, I < 30 mA mains power supply unit (in conjunction with a serial interface)

Keypad with 4 buttons

2-line dot-matrix display with plain-text description of the values displayed.

All parameters, settings and archived values can be displayed.

3 digital inputs for connecting LF pulse generators and message signals (e.g. manipulation contact)

Absolute sensor, Type ENVEC CT30*, integrated in housing or, as an option, provided as an external sensor

for volume conversion

(if two pressure sensors will be used, then one as internal and one as external version), connection for precision steel pipe (Ermeto 6L) or fl exible pressure tube, M12 x 1.5 threadPressure ranges 0.7 – 2 bar / 0.8 – 5 bar / 1.4 – 7 bar / 2 – 10 bar / 2.4 – 12 bar / 4 – 20 bar / 6 – 30 bar / 8 – 40 bar /

14 – 70 bar / 16 – 80 bar

* Other sensors and pressure ranges on request

Absolute or gauge sensor, Type ENVEC CT30, provided as an external sensor,

for monitoring purposes

fi xed connection to the central unit, 10 metres fi xed cable length

connection for precision steel pipe (Ermeto 6L) or fl exible pressure tube, M12 x 1.5 threadAbsolute pressure ranges between 0.7 – 80 bar (see above)Gauge pressure ranges: 1.4 – 7 bar / 4 – 20 bar / 16 – 80 bar

Temperature sensor

Pt-500 (or Pt-100 as an option) resistance thermometer to DIN 60751 with protective tube, for use with thermowell.

- Fitting length 50 mm Ø 6 mm, length of supply cable 2.5 m

Calculation in accordance with S-GERG 88, AGA 8 detailed, AGA 8 (GC1 or GC2), AGA NX-19, AGA-NX19 following Herning & Wolowsky or fi xed

2 monthly archives, 1 daily archive, 1 measurement archive (content and recording interval are fi xed)1 process data archive, 1 measurement archive, 4 additional fl exible archives (content, recording interval and additional events which cause a record can be selected)

- Recording of non-periodic events (e.g. time changes with time stamp)

- Storage capacity 500 recordsChange logbook (audit trail)

- Recording of all parameter and value changes (time stamp, old and new values)

- Storage capacity 200 recordsCertifi cation data log

- Recording of changes of certain parameters and values (time stamp, old and new values),

which are normally under the access rights of the calibration lock

- Storage capacity 50 records

4 digital transistor outputs, freely programmable and protectable via calibration lock as

- Pulse output for all operating or standard volume meters

- Signal output for alarm and/or warning status information

Optical interface in accordance with IEC 62056-21Internal serial interface usable as RS232 or RS422/RS485

Communication protocols

- IEC 62056 21 (IEC 1107)

- Modbus Modbus ASCII / RTU / TCP

- SMSOther communication protocols on request

Elster-Instromet Sdn. Bhd. (Singapore Branch)

Steinern Str. 19 - 21

29 Tai Seng Avenue

55252 Mainz-Kastel

#06-05A Natural Cool Lifestyle Hub

T +49 6134 605 0

T +32 3 670 0700

F +49 6134 605 223

F +32 3 667 6940

Vital Connections

Copyright 2012 Elster GmbH

All rights reserved.

Subject to change without prior notice

Source: http://www.fagas.ba/img/site/files/DS_EK220_EN.pdf

Agriculture and Natural Resources Growing American Ginseng in Ohio: Chip Carroll Dave Apsley Rural Action Sustainable Forestry Natural Resources Specialist and Appalachian Forest Resources Center Ohio State University Extension American ginseng (Panax quinquefolium), one of the world's most valued plants, is found throughout the

API 5000™ LC/MS/MS System The world's most sensitive LC/MS/MS system. A new benchmark for quantitativesmall molecule analysis. The API 5000™ LC/MS/MS system is today's most sensitive triple quadrupole mass spectrometer for complex bioanalytical samples. Designed to deliver the lowest limits of detection for the most demanding DMPK and ADMET studies, the system